Are you passionate about watches? Do you want to understand how a watch works and learn new technical vocabulary? You have certainly heard of the barrel and the barrel spring!

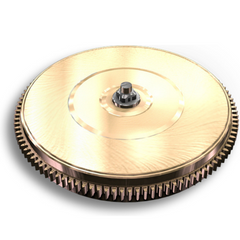

The barrel is a small cylindrical metal case. Equipped with small teeth, it ensures the functioning of the watch. Inside this box is a spring called "mainspring" or "barrel spring". What is a barrel spring? What is its purpose? How do you change it, put it back in its place?

-

The main components of a mechanical watch

Watches are all different from each other. There are many models and some even have watch complications to display the hours, minutes, seconds, date, lunar cycle etc. Mechanical watches are particularly popular with watchmakers and collectors.

For simple mechanical watches, the main organs are: the motor organ (barrel), the transmission organ (the gear train), the distribution organ (anchor and anchor wheel), the regulation organ (the balance spring) and the display organ (time setting function).

Mechanical watches come in two versions, automatic mechanical and manual mechanical. These watches are different from quartz watches which require a battery (creation of an electrical impulse to set a quartz watch into oscillation).

-

What is a barrel spring?

The barrel spring plays an extremely important role in the mechanism of a watch. It is the source of kinetic energy. It is hidden in the barrel and under other components. The mainspring exists in all mechanical (hand-wound) and automatic watches.

The barrel stores the force of the spring and supplies the watch with the energy necessary for its operation. The choice of materials for the manufacture of this spring is not made at random. Indeed, the barrel spring must resist mechanical stresses. Its geometry is both isotropic and homogeneous.

This impressive timepiece was invented in the 15th century. The invention of the mechanical watch with barrel spring is often attributed to the German watchmaker Pierre Henlein.

Before the spring, mechanical clocks were operated by a suspended weight. They were much heavier, had little autonomy, were not very accurate and, above all, took up a lot of space.

-

How does a mechanical watch work?

It is the tension of the barrel spring that makes a mechanical watch work.

The mechanism of a mechanical watch is both simple and impressive! All watches need a power source to function. Mechanical models must be wound daily by hand. A mainspring stores energy when it is contracted. The crown gear in the barrel transfers the energy released by the barrel spring to the gear train.

The gear system also ensures the transfer of this energy through the watch. "But what ensures the continuity of the watch movement? The distribution organ (the escapement) will transform this continuous fore into an alternative face. To release the kinetic energy, the mainspring relaxes very slowly, performing 1/9 or 1/6 of a rotation per hour. The transmission of energy is carried out in a regular and precise way.

-

What is the function of the barrel spring?

The barrel spring is a mechanical part that serves to provide and restore kinetic energy. This small metal strip is essential for the functioning of mechanical watches. It is one of the components of the barrel. In the middle of this mainspring is a shaft (barrel shaft).

The barrel spring is attached to both the barrel at the outer spiral and to the central shaft at the inner spiral.

If the watch is manually wound, the spring is contracted by means of the winding stem. For automatic watches, the winding is also done with the automatic system and the oscillating weight. The invention of the barrel spring was a huge step forward in the world of watchmaking. Before the invention of the spring it was impossible to imagine a portable timepiece.

The barrel spring is nowadays manufactured from a complex alloy of specific materials. It must have a high coefficient of elasticity, be stainless, non-magnetic and fatigue-proof.

How do I refit / change a barrel spring?

Barrel springs can be found everywhere, not only in watches, but also in old clocks, alarm clocks or even in spindle turners.

Disassembling a mechanical movement and putting the spring back in place requires patience.

You have removed the barrel spring to clean it. You will then need an estrapade (a tool to roll the spring into the cylinder so that it can be pushed out later) to put it back in place.

If you need to replace the spring with a new one, (in a ring) you must first push the aluminium ring, on the end of the spring, before presenting it in the drum (pay attention to the direction of installation of the spring).

Then apply pressure with a screwdriver to lower the spring into the drum. Make sure that the entire barrel spring is in its place in the drum.

-

To summarise

When tensioned, the barrel spring accumulates the kinetic energy necessary for the operation of the watch.

This small metal ribbon, with its strong elasticity, is always wound in the barrel. Its dimensions vary according to the model of the watch. Its diameter varies from 5 mm to about 20 mm.

In some mechanical watches with alarms, there are two barrels, one to store the energy needed to display the time and the other to store the energy needed to trigger the alarm via a small hammer.

Installing/changing a barrel spring requires experience and the right set of tools!

Image credits :

https://www.hautehorlogerie.org/fr/watches-and-culture/encyclopedie/lexique-de-lhorlogerie/s/barillet/

http://archive.horlogerie-suisse.com/journal-suisse-horlogerie/technique/description-montre-suisse-ressort_et_barillet-12531008.html

https://generaleressorts.com/produits/